Factory

Our Factory

Our factory is a facility that specializes in the production of calcium carbonate, a compound commonly used in various industries. This factory typically utilizes advanced machinery and processes to extract and refine calcium carbonate from natural sources such as limestone or marble. The end product is then sold to other industries for applications such as paper manufacturing, construction materials, pharmaceuticals, and food additives.

Calcium Carbonate

The process of a calcium carbonate factory involves several steps. Firstly, limestone is extracted from quarries and transported to the factory. Then, the limestone is crushed into smaller pieces and heated in a kiln to produce quicklime. Next, the quicklime is combined with water to create slaked lime. Finally, carbon dioxide gas is passed through the slaked lime solution to precipitate calcium carbonate, which is then dried and processed into various forms for different applications.

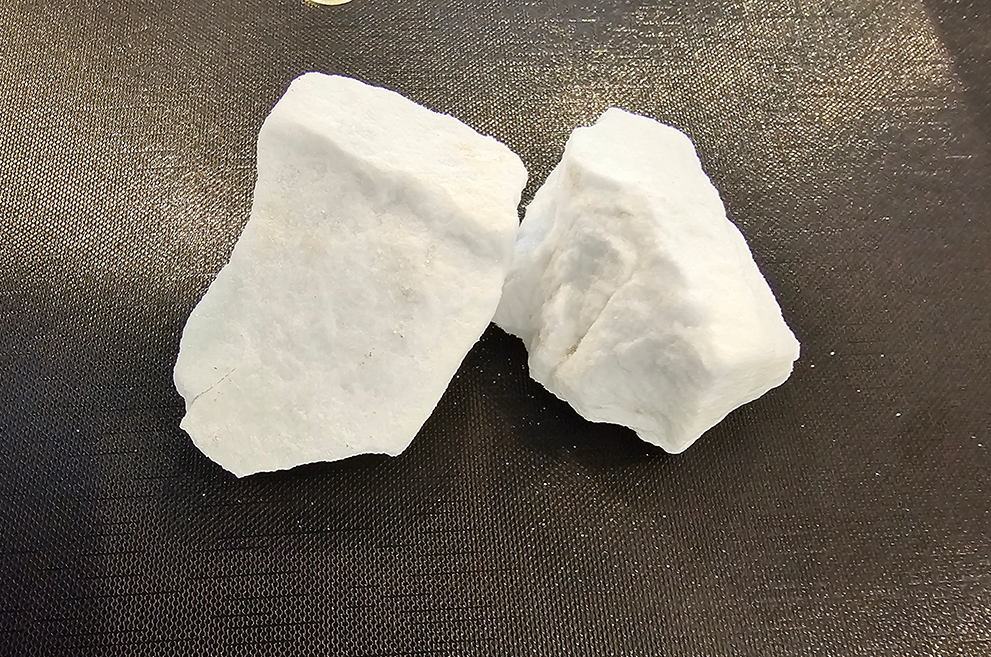

Dolomite

Dolomite is a mineral that is formed through the process of sedimentation and metamorphism. It starts with the deposition of calcium carbonate-rich sediments, which over time undergo compaction and lithification. As the sediments are buried deeper in the Earth’s crust, they experience high temperatures and pressures, causing the calcium carbonate to recrystallize into dolomite. This process is known as diagenesis, where magnesium-rich fluids replace some of the calcium in the mineral structure, resulting in Factory

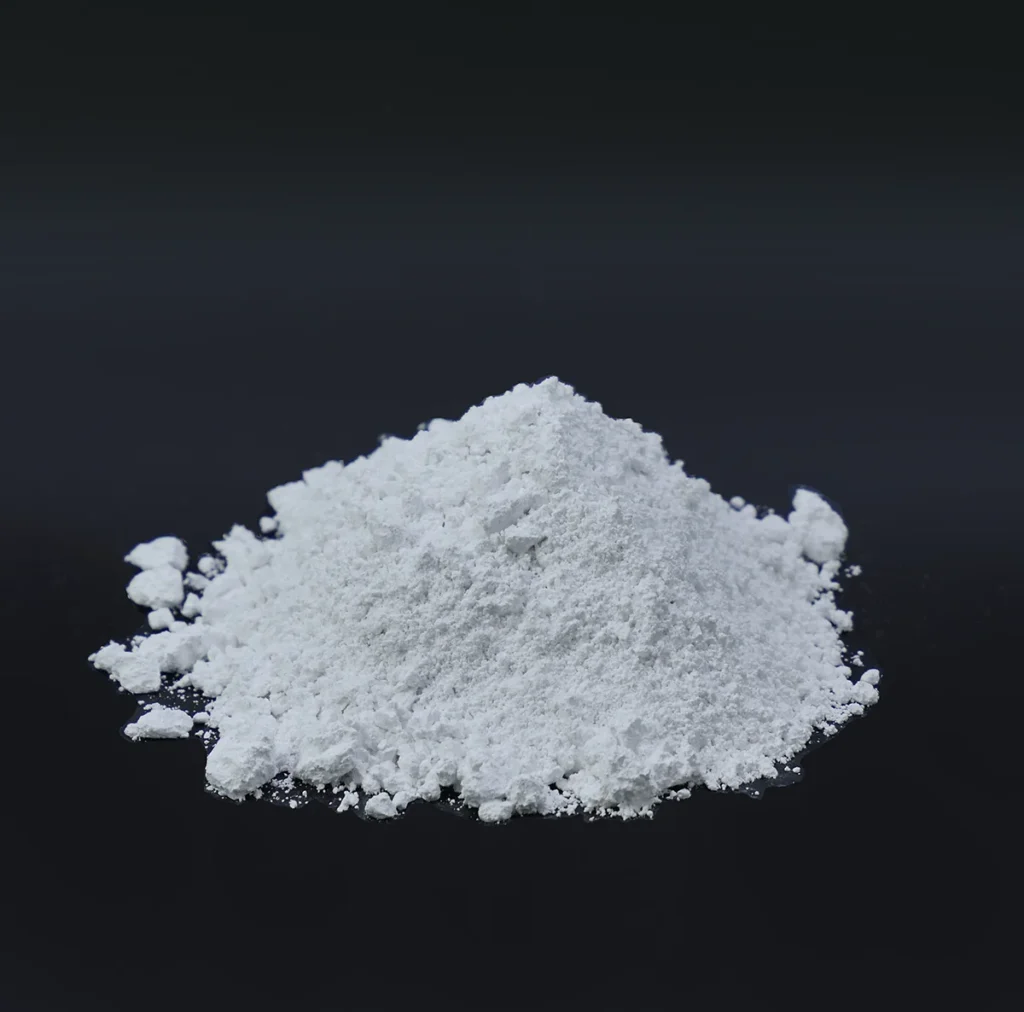

Talc

The process of a talc factory involves several steps. Firstly, the raw talc is extracted from mines and then undergoes a thorough cleaning process to remove impurities. After cleaning, the talc is crushed into fine particles and then sorted based on its quality.

Next, the sorted talc is subjected to various milling techniques to achieve the desired particle size and consistency. This involves grinding the talc into a powder form using specialized machinery. The powdered talc is then carefully packaged and prepared for distribution

Ditomite

The process of a Ditomite factory involves several steps. Firstly, the raw ditomite material is extracted from mines or quarries. It is then transported to the factory where it undergoes crushing and grinding to achieve the desired particle size. After this, the ditomite is subjected to a series of purification processes to remove impurities and contaminants. Finally, it is dried and packaged for distribution or further processing into various products such as filters, insulation materials, or fertilizers.